Dubai is rapidly emerging as a global leader in adopting advanced technologies to drive sustainability and economic growth. Among these technologies, 3D printing stands out for its potential to revolutionize manufacturing and supply chain processes.

The use of 3D printed spare parts is playing a crucial role in supporting Dubai’s sustainability initiatives by reducing waste, minimizing carbon footprints, and promoting circular economy practices. This article explores how 3D printed spare parts contribute to Dubai’s sustainability goals.

Reduction of Material Waste

Additive Manufacturing Efficiency

One of the most significant advantages of 3D printing Dubai is its additive manufacturing process. Unlike traditional subtractive manufacturing methods, which involve cutting away material from a larger block, 3D printing builds parts layer by layer.

This method significantly reduces material waste, as only the necessary amount of material is used to create the part. In Dubai, where resource efficiency is a priority, this reduction in waste aligns perfectly with sustainability objectives.

Optimized Material Usage

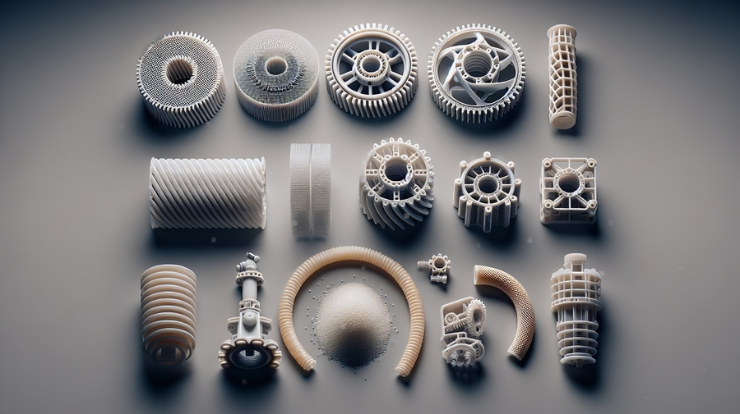

3D printing allows for precise control over material deposition, enabling the production of parts with optimized geometries and minimal waste. This optimization is particularly beneficial for producing complex spare parts that would otherwise generate significant scrap in traditional manufacturing. By using materials more efficiently, Dubai’s industries can reduce their environmental impact and lower production costs.

Energy Efficiency and Lower Carbon Footprint

Energy-Efficient Production

The energy consumption of 3D printing is generally lower compared to traditional manufacturing processes. For example, processes such as CNC machining and injection molding require significant energy for material removal and mold creation, respectively.

3D printing, on the other hand, uses energy primarily for layer-by-layer construction, which is more efficient and less energy-intensive. This energy efficiency contributes to Dubai’s efforts to reduce industrial energy consumption and greenhouse gas emissions.

Reduced Transportation Emissions

3D printing enables localized production of spare parts, reducing the need for long-distance transportation. Traditional supply chains often involve shipping parts from centralized manufacturing facilities to various global locations, contributing to carbon emissions. By producing spare parts locally in Dubai, businesses can significantly cut down on transportation-related emissions, supporting the city’s commitment to reducing its carbon footprint.

Promotion of Circular Economy Practices

On-Demand Manufacturing

3D printing supports on-demand manufacturing, which means parts are produced only when needed. This approach minimizes overproduction and excess inventory, key components of a circular economy. In Dubai, where space and resources are at a premium, on-demand manufacturing helps businesses manage inventory more sustainably and reduce waste associated with unsold products.

Recycling and Reuse of Materials

Many 3D printing processes allow for the use of recycled materials, contributing to the circular economy. For instance, thermoplastic filaments used in 3D printing can be recycled and reused multiple times. By incorporating recycled materials into the production of spare parts, Dubai’s industries can reduce their reliance on virgin materials and promote sustainable resource use.

Extended Product Lifespan

Efficient Spare Parts Production

The ability to produce spare parts quickly and efficiently extends the lifespan of existing products. Instead of discarding products due to the unavailability of spare parts, businesses and consumers can use 3D printing to create replacement parts, ensuring continued functionality. This practice reduces the volume of waste generated from prematurely discarded products and supports sustainable consumption.

Customization and Fit

3D printing allows for the customization of spare parts to fit specific requirements, ensuring better compatibility and performance.

Customized spare parts can enhance the efficiency and longevity of products, reducing the need for frequent replacements. By extending product lifespans, Dubai’s businesses can contribute to a more sustainable consumption model and reduce overall waste.

Innovation in Sustainable Materials

Development of Eco-Friendly Materials

The 3D printing industry is continuously evolving, with significant advancements in sustainable materials. Researchers and manufacturers are developing bio-based and biodegradable materials that can be used in 3D printing.

Dubai’s commitment to innovation and sustainability drives the adoption of these eco-friendly materials, reducing the environmental impact of spare parts production.

Lightweight and Efficient Designs

3D printing enables the creation of lightweight designs without compromising strength and functionality. Lighter parts require less material and energy to produce and transport, contributing to overall sustainability. In sectors like aerospace and automotive, where weight reduction is critical, 3D printed spare parts offer substantial environmental benefits.

Support for Local Manufacturing Ecosystems

Boosting Local Economy

By encouraging local production of spare parts, 3D printing supports Dubai’s economy and reduces dependence on international supply chains. Local manufacturing ecosystems contribute to job creation and economic resilience, aligning with Dubai’s vision for sustainable growth.

Resilience to Supply Chain Disruptions

The COVID-19 pandemic highlighted the vulnerabilities of global supply chains. 3D printing offers a solution by enabling localized and decentralized production of spare parts. This resilience is crucial for maintaining business continuity and supporting sustainable practices in the face of global disruptions.

Conclusion

The integration of 3D printed spare parts into Dubai’s manufacturing landscape is a significant step toward achieving sustainability goals.

By reducing material waste, lowering energy consumption, promoting circular economy practices, extending product lifespans, innovating in sustainable materials, and supporting local manufacturing, 3D printing plays a pivotal role in Dubai’s sustainability initiatives.

As the technology continues to advance, its potential to drive sustainable development in Dubai will only grow, solidifying the city’s position as a leader in innovation and environmental stewardship.